Store collaboration with

Studio GdB

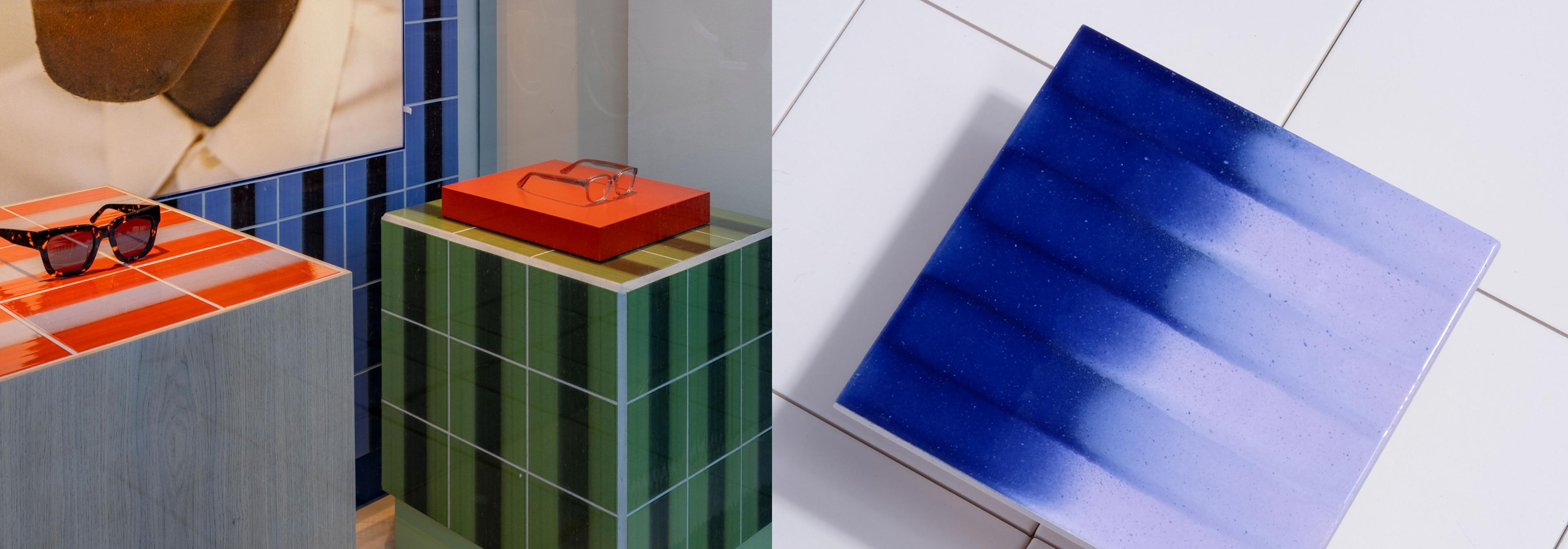

For our latest Brussels store, we worked with Studio GdB and their cutting-edge, custom tiles. Together with like-minded creatives, we’re using our stores to stage fresh perspectives on retail design. Conventional techniques didn’t cut it for this studio, so they developed their own — keep on reading for more.

Meet the studio

Gilles de Brock and Jaap Giesen are the experimental duo behind Studio GdB. With years of experience in graphic design, they’ve explored silkscreen printing, designing clothing and hand tufting carpets — to name a few. Nowadays, they’ve found their calling in ceramic tiles.

Tiles, you say? Yes, Studio GdB has turned the humble square into an art form. Their penchant for experimentation leads to contemporary compositions, still, with that raw, handmade feel you can find in traditional ceramic glazing.

(Ace & Tate) Striking patterns, vibrant hues — what’s the story behind your unique approach to ceramics?

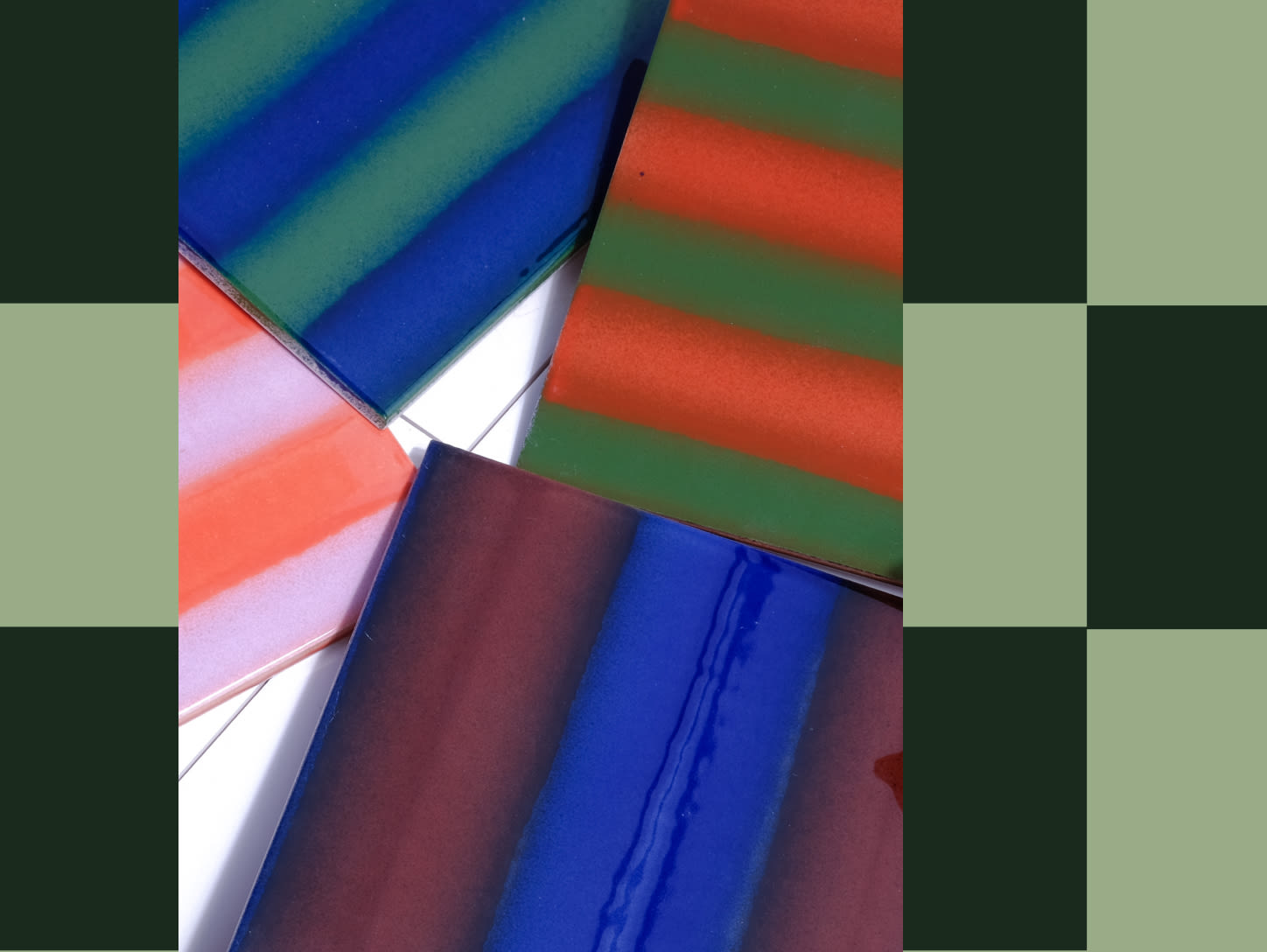

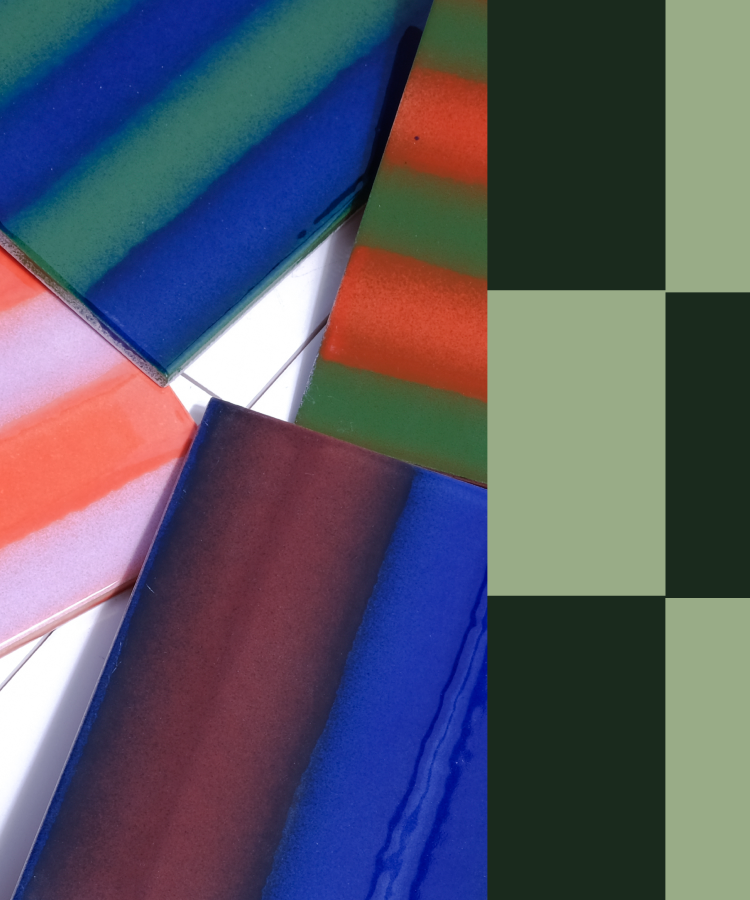

(Studio GdB) As Graphic Designers, we did a lot of silkscreen printing — where colour always plays a large role. In silkscreen printing, we’ve had to be very precise and were limited in the colours we could use. We took our experience in this field and translated it into the ceramics we make today.

And you make your own colours?

Yes, we make our own recipes for colours. It feels like being a mad scientist. Our recipes are very precise, and sometimes something strange happens during the firing process leading to unexpected results, aka pleasant surprises. It’s satisfying for us to work this way because the compositions start to resemble each other and almost rhyme in some strange way.

What inspires your work?

Definitely painters like Sean Scully and interior designers like Shauwn Hausman. Now that we’re developing machines, we also find inspiration in watching industrial production lines.

“We make our own recipes for colours. It feels like being a mad scientist.”

The ingredients

What started off as a blank canvas, became a dashing display of colours and patterns. Lucky for us, Studio GdB was brimming with ideas right off the bat. “It’s great to work with a client that is open to experimenting and wants to go the extra mile,” says the studio. Here’s what it took to bring it all together.

A blank canvas

Studio GdB’s artwork was the starting point for the interior direction of our Brussels store. The three colour combinations they created were applied to the store’s walls and furniture — creating a space that truly pops in colour.

The right colours

Ceramics get their colour from glazes — which Studio GdB make from different ingredients and customise by adding stains (essentially coloured glass powders). They make variations of a recipe, fire the results and continue experimenting until they had the perfect hues.

A custom-built machine

They created their own CNC (computer numerical control) ceramics machine. With that, creating software that translates their designs to instructions the machine can follow — allowing them to make any design they like.

A kiln

To get those vivid compositions and colours, they create a glaze by firing the different ingredients. You have to deal with fluxes that lower the melting points of certain ingredients, see what pigments counter react and so on. Like they said, mad scientist vibes.

Responsible design

Part of rethinking the traditional ceramics process means finding methods and approaches that are better for the environment. We asked them to elaborate a little on what that means for this collaboration.

What are some ways you’ve made the design process more sustainable?

For starters, we try to use as many recycled materials as possible. The base product of our tiles is made from recycled materials that come from the sewer system in Maastricht. We ourselves, collect our waste in our production facility and recycle it into a special glaze collection. We also develop all our colours to work best in electric kilns. This is much less common in the ceramic industry than a gas kiln but far better for the environment.

Can you tell us more about your partner, Mosa?

Yes, Mosa supplies the base tiles for us. They’re a Cradle to Cradle Certified company and have created a tile that’s almost too good to be true. They offer a reliable product and make sure the production is circular, everything is optimised, recycled materials are used and all the waste that gets made gets recycled as well.

Like what you see on screen? It looks even better IRL. Our doors are open, so swing by and come say hi.

Photos by Studio GdB and Wouter van der Sar.