Our Materials

Quality materials and manufacturing are central to everything we do. Your glasses go through a lot, so we need to make sure they’re up to the job.

Making products with care

Since 2018, we actively strive to incorporate sustainable materials into our

collection, without compromising the quality standards that define Ace & Tate. We work

closely with our manufacturers, who meet our standards of social and environmental

responsibility, and we'll continue to seek innovative materials and technologies to create well-designed, quality frames.

Acetate

Most of our frames are made of acetate. Regular acetate is a mixture of cellulose acetate (wood pulp or cotton fibres, combined with acetic anhydride) and a conventional plasticiser. Acetate is strong, light, hypoallergenic, and easily repairable, not to mention endlessly colourful and customisable. Our design studio in Amsterdam makes some of our acetate designs from scratch, making them truly one-of-kind.

Acetate Renew Bio

Acetate Renew Bio is a lower-impact alternative to regular and bio acetate. The CO2 footprint of an Acetate Renew Bio frame shows a 9% reduction* compared to a bio acetate frame. Like regular acetate, Acetate Renew Bio is made from FSC-certified wood pulp (42%), but is combined with certified recycled contents** (28%) instead of acetic anhydride. We then combine the cellulose acetate flakes with bio-based plasticisers (30%) to create the final acetate material.

*Source: Ace & Tate 2024 LCA, using primary data from Eastman

** ISCC-certified recycled contents, obtained via mass balance

Recycled Acetate

Recycled acetate provides a more sustainable alternative to bio acetate and Renew Bio acetate, reducing waste while preserving its familiar qualities and feel. It's crafted from pre-consumer waste, which includes off-cuts generated during production that are then dyed. The CO2 footprint of a recycled acetate frame shows a 14% reduction* compared to a bio acetate frame and a 5% reduction* compared to a Renew Bio acetate frame.

*Source: Ace & Tate 2024 LCA

100% of our acetate collection consists of lower-impact materials (Bio Acetate, Recycled Acetate or Acetate Renew Bio).

Bio Acetate

Bio acetate uses a plasticiser made from renewable materials, such as citric acid, instead of fossil fuels. Overall, the estimated CO2 footprint for our bio acetate frames shows a 2.5%* higher impact than our regular acetate frames. The slightly higher estimated impact, well within the range of uncertainty, comes from the bio-based plasticiser, a material for which limited reliable emissions data currently exists. Despite this, we prefer the bio-based plasticiser because it helps reduce reliance on non-renewable resources, which we believe is a step towards sustainability.

*Source: Ace & Tate 2024 LCA

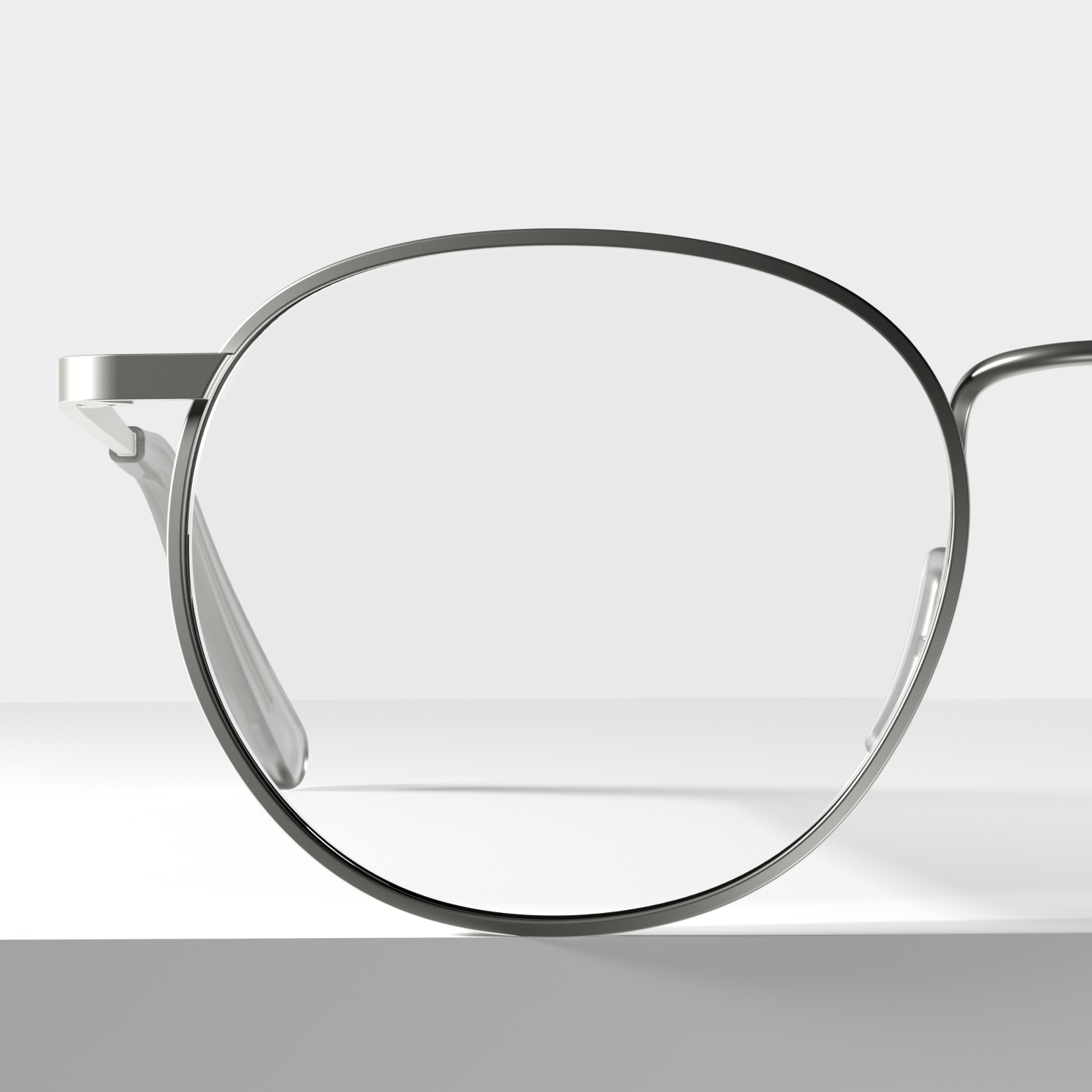

Metal

Our collections also feature metal frames — cut from stainless steel or titanium. These materials are very durable and feel incredibly light. Stainless steel frames feature a slim profile and are lighter than acetate frames. Titanium frames are even lighter and more flexible, making them resistant to breakage.

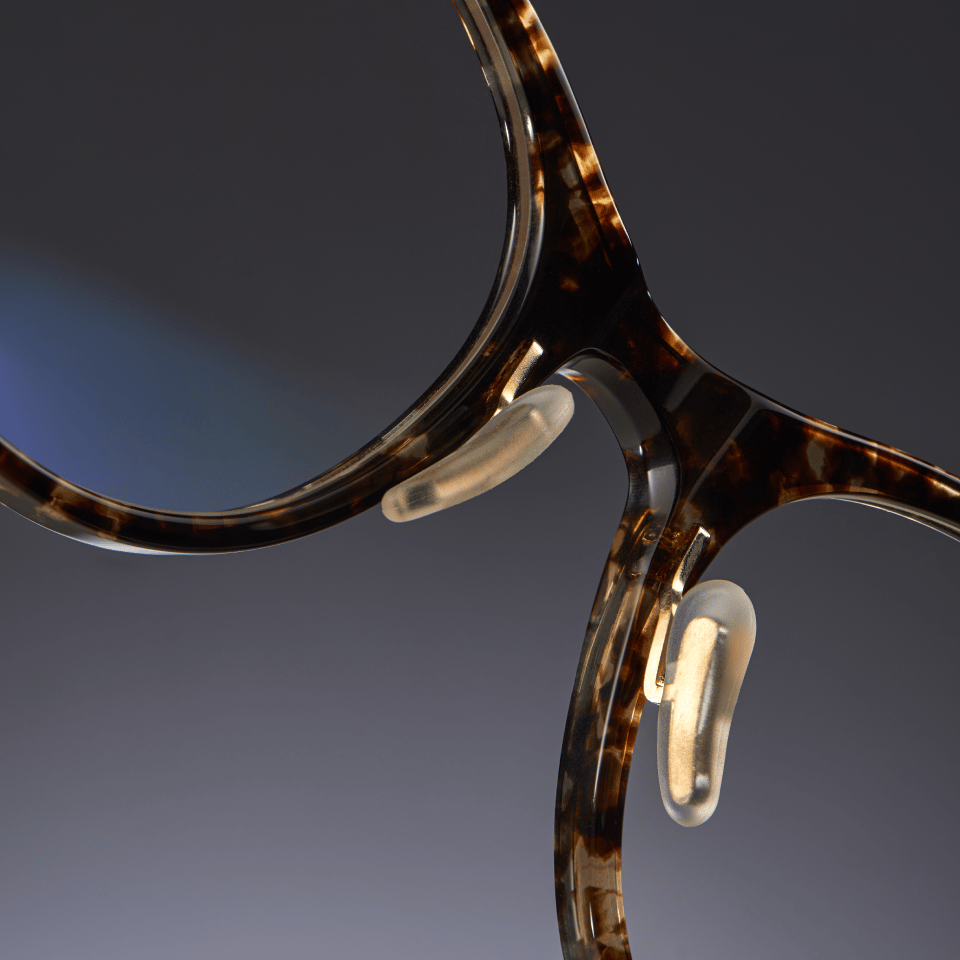

Metal components

Each of our frames has metal components to keep it all together, including hinges and custom core wire. These are carefully designed by German engineers before being crafted at their factory in Shenzhen.

Packaging

Our shipping box has been reduced to the smallest size possible, and is made from 30% virgin grass fibres and 70 % recycled, FSC-certified paper.

Lenses

Our prescription lenses are made from CR-39, a strong polycarbonate material. They have been treated with anti-reflective and scratch-resistant coatings to ensure strength, clarity and comfort. The majority of our (non-prescription) sunlenses are now made of Tritan Renew, which consists of 50% recycled materials.